The Schmidt-Kupplung

The coupling for an extreme offset

The Schmidt-Kupplung is a compact, torsionally stiff high-performance coupling for a large, variable radial offset. The angle synchronisation of the connected shafts is retained at all times. The modular design allows the torque and displacement to ideally adapt to their specific requirements.

The Schmidt-Kupplung coupling is used in a variety of applications, such as in printing machines, profiling systems, packaging machines and coating facilities.

Large offset with absolute angle synchronisation

The Schmidt-Kupplung coupling is a compactly built coupling for precise torque transmission of extremely radially offset shafts. The shaft offset can be changed both at rest and while running under load, to any value within the required permissible swivel range. In this process, permanent angle-synchronous transmission is ensured regardless of the shaft offset height. From one drive to the other, they operate permanently in synchronisation, with no phase shift.

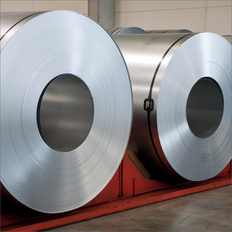

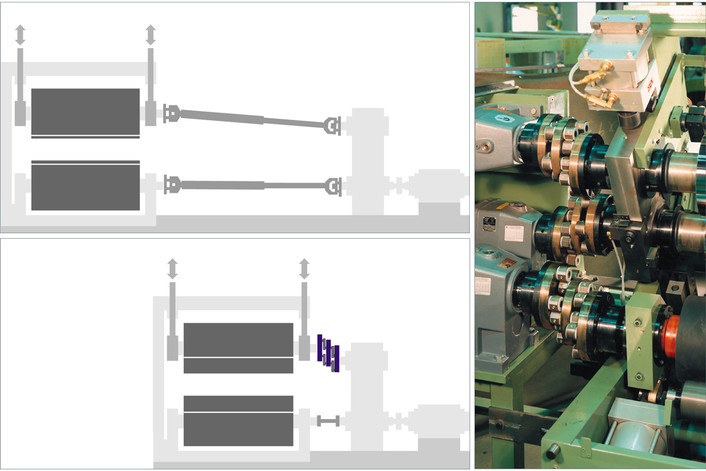

Figure 1.2: Application for roller drives such as coating rollers; various material thicknesses are processed. The Schmidt-Kupplung coupling allows variable functional shaft offset in the machining process during operation while in continuous synchronisation.

Picture 3: Turning the roller without stopping the machine. The roller can be replaced during operation. This eliminates any cost-intensive start-up for the machine.

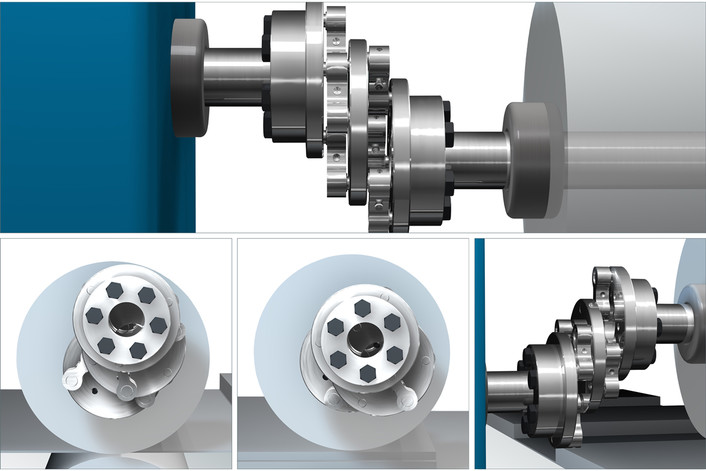

Precise and compact

The coupling runs with three discs and two link levels. This ensures compactness and torsionally stiff work. The additional use of precision needle bearings in the coupling links ensures very low rotational play and thus ensures precise torque transmission.

High torsional stiffness, no restoring forces

The components of the Schmidt-Kupplung coupling are made of high-quality steel with high tensile strength and tempered steel.

It offers high torsional stiffness as an all-metal coupling and is designed for high torque transmission.

The Schmidt-Kupplung coupling compensates shaft offset without any restoring forces and thus bearing loads.

Figure: The space-saving and precision choice for roll-forming machines

Comparing to cardan-shafts the Schmidt-Kupplung builds significantly more compact for modern space-saving applications. Additionally the coupling has a higher torsional stiffness, less backlash and works more precisely. The Schmidt-Kupplung coupling is a dynamically balanced system. Radial vibration is absorbed by the coupling.